A-frame Cranes - Customized as Needed, Helping Factories, Ports, and Construction Sites Operate Efficiently

Application

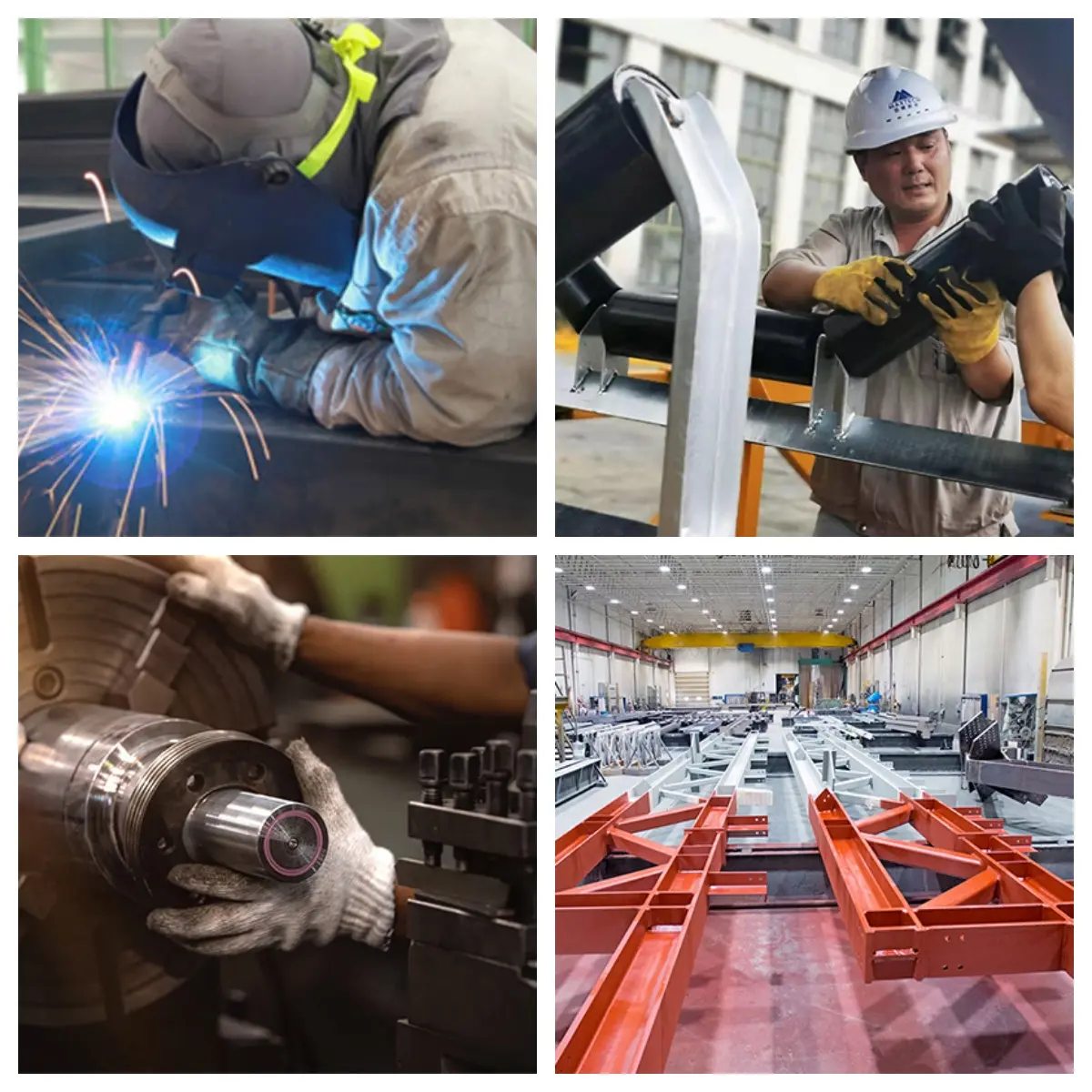

Maxtech A-frame cranes are widely used in various industrial scenarios.

1.In factory workshops, they can efficiently handle heavy machinery, raw materials, and finished products, improving the material transportation efficiency on the production line.

2.At port terminals, A-frame cranes can undertake important tasks such as container loading and unloading and bulk cargo lifting. With their powerful lifting capacity and stable performance, they ensure the smooth operation of port operations.

3.At construction sites, whether it is lifting building materials or assisting in the installation of large building components, A-frame cranes can play a crucial role in facilitating the smooth progress of projects.

Model Ranges

We provide two basic types of gantry cranes: single-girder and double-girder, and each type is available in rail-mounted and rubber-tyre versions.

1.Single-girder gantry cranes are suitable for places with relatively small lifting weights and limited space. Their lightweight structure enables flexible operation.

2.Double-girder gantry cranes, on the other hand, have a greater lifting capacity and can handle heavier cargo lifting tasks. They are suitable for large factories, ports, and other environments that require high-intensity operations.

3.Rail-mounted gantry cranes are suitable for long-distance and high-precision lifting operations on fixed tracks;

4.rubber-tyre gantry cranes are highly mobile and can quickly move between different work areas, adapting to complex and changeable work sites.

| main technical parameter |

|

| SWL | 65t |

| Max hoisting height | 4.1m |

| Hoisting speed | 5m/min |

| Hoisting speed | ≈2500mm² |

| Back to the side of the hook to the side | ~3850mm² |

| Amplitude variation time | 120s |

| Distance between the center of the two legs | 3.5m |

| Power | 75 kW×2 |

| Working system | S6 - 40% |

| Voltage | 380V 50Hz 3ph |

| Level of protection | IP56 |

| Allowable tilt of ship | heel≤5°/trim≤10° |

Features

1.Customization Service: We understand that each customer's working environment and requirements are different, so we offer fully customized services. You only need to provide us with detailed information such as lifting capacity, span, lifting height, power source, etc. Our professional team will quickly provide you with an accurate quotation and design the most suitable crane solution for you.

2.Multiple Operation Modes: The standard configuration is a push-button remote control. At the same time, we also offer optional operation modes such as push-button remote control and joystick cabin control to meet the operating habits and working scenarios of different customers.

3.Powerful Lifting Capacity: The maximum lifting capacity of our standard cranes can reach 600 tons (the lifting capacity of electric hoists can reach 80 tons). If the standard products cannot meet your special requirements, we can provide customized solutions to ensure that every operation requirement of yours is met.

4.Adapt to Various Spaces: For workshops with low headroom, we have specially designed products. You can consult our professional engineers for detailed dimensions and technical details. They will provide you with the best solution to ensure that the crane can operate efficiently in limited spaces.

5.Safety Design: Maxtech gantry cranes have a high safety factor and a long service life. The lifting mechanism adopts an innovative design, which extends the service life of the wire ropes; the rotating mechanism is also innovatively optimized, featuring high load capacity, long service life, and a safety interlocking device, ensuring operation safety in all aspects.

Service

1.Professional Team Support: We have a team of professional mechanical and electrical engineers. They will tailor the most suitable solution for you according to your specific needs, ensuring that the crane performance perfectly matches your operation requirements.

2.Overseas Service Support: Our engineers are always ready to provide on-site services to overseas customers, promptly solving problems encountered during equipment installation, commissioning, and maintenance to ensure the normal operation of the equipment.

3.After-sales Maintenance Guarantee: We provide approximately 12 months of maintenance services. When we receive customer feedback on quality issues, relevant after-sales service managers will respond immediately to assist customers in solving problems, ensuring that customer rights and interests are protected.

description2