MAX 310 Transshipment Crane: Compact Powerhouse for Versatile Cargo Handling

Application

The MAX 310 transshipment crane shines in multiple applications. In smaller ports and harbors, it efficiently manages the loading and unloading of general cargo, containers, and bulk materials, streamlining the logistics process. For industrial facilities near waterways, it serves as a reliable workhorse for transporting heavy machinery and equipment between storage areas and production lines. In shipyards, the crane’s precise control allows for the delicate handling of ship components during construction and repair. Its ability to operate in a wide range of ambient temperatures and weather conditions makes it suitable for both coastal and inland operations, providing consistent performance across different geographical locations.

Model Ranges

| Speeds | |

| Hoisting/lowering | |

| Hoisting/lowering up to 10 t SWL | 0 m/min – 130 m/min |

| Hoisting/lowering with 30 t SWL | 0 m/min – 64 m/min |

| Hoisting/lowering with 45 t SWL | 0 m/min – 43 m/min |

| Slewing | |

| Speed | 0 rpm – 1.2 rpm |

| Range | 360 ° unlimited |

| Luffing time (from 5.1–30 m approx.) | |

| Maximum luffing time (jib length 30 m) | approx. 45 sec |

| Design conditions | |

| Maximum admissible | |

| Heel/trim | 5 °/2 ° |

| Ambient working temperature | -20°C to +45°C |

| Humidity maximum | 93 % |

| Maximum wind speed | |

| Working condition | 20 m/sec |

| Parking condition | 63 m/sec |

Features

1.High - speed Hoisting: Achieves up to 130 m/min with 10 t loads, ensuring fast cargo handling, and maintains stable operation for heavier 30 t and 45 t loads.

2.Flexible Maneuvering: With 0 - 1.2 rpm slewing speed and 360° rotation, it navigates tight spaces easily for accurate load positioning.

3.Efficient Luffing: Completes 30 m jib luffing in about 45 sec, reducing repositioning time.

4.Harsh - environment Ready: Operates in -20°C to +45°C and 93% humidity, withstanding 20 m/sec working and 63 m/sec parking winds.

5.Stable Operation: 5°/2° heel/trim tolerance ensures stability during heavy - load handling on uneven surfaces.

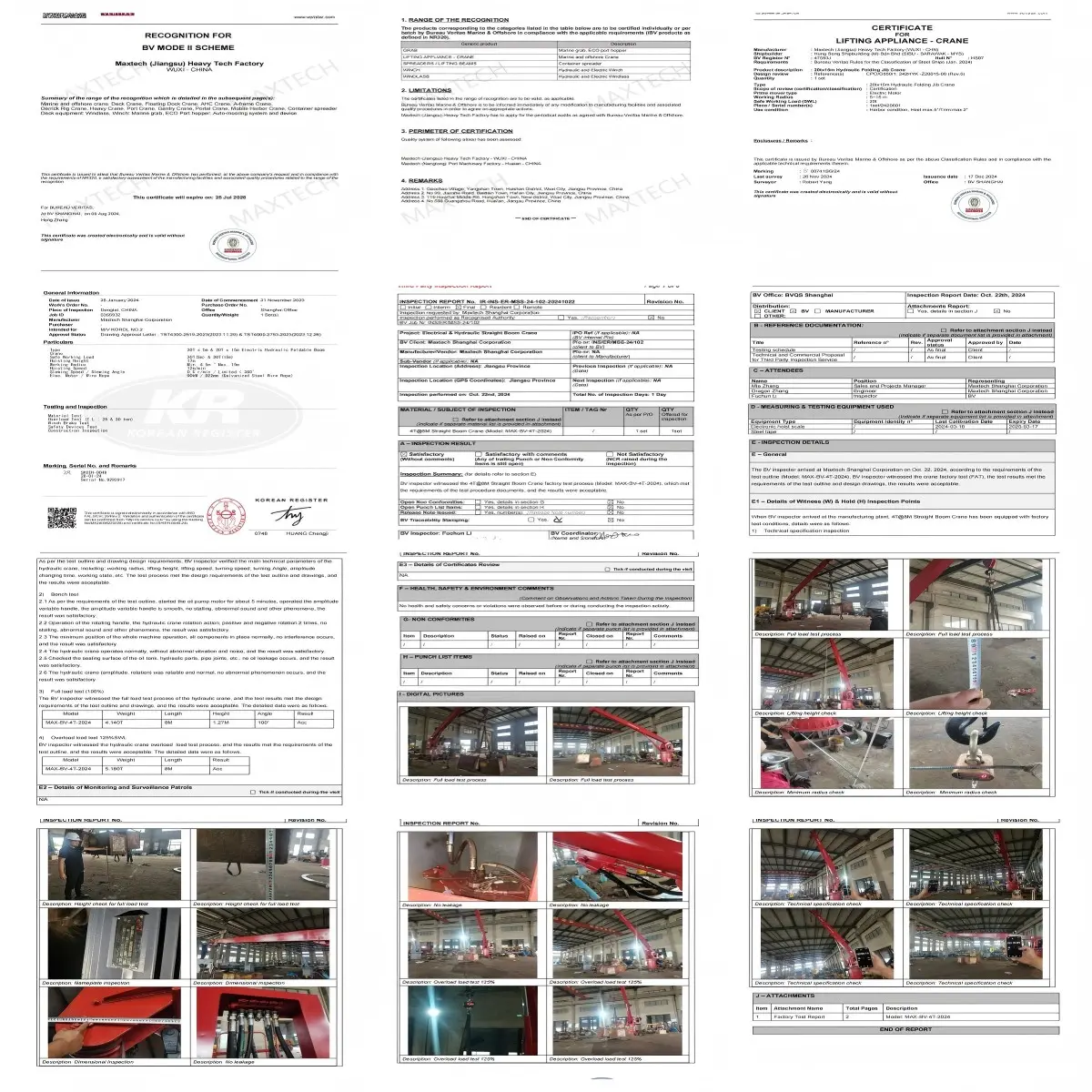

Certificates and Qualifications:

2.Testing and Certification

Before leaving the factory, the equipment needs to undergo strict tests, including performance tests (lifting, luffing, and slewing movements with rated and overload loads), emergency stop confirmation, manual brake release tests, limit switch confirmation (under no - load conditions), and insulation resistance measurement. The test records of each item will be submitted to users to ensure reliable product performance.

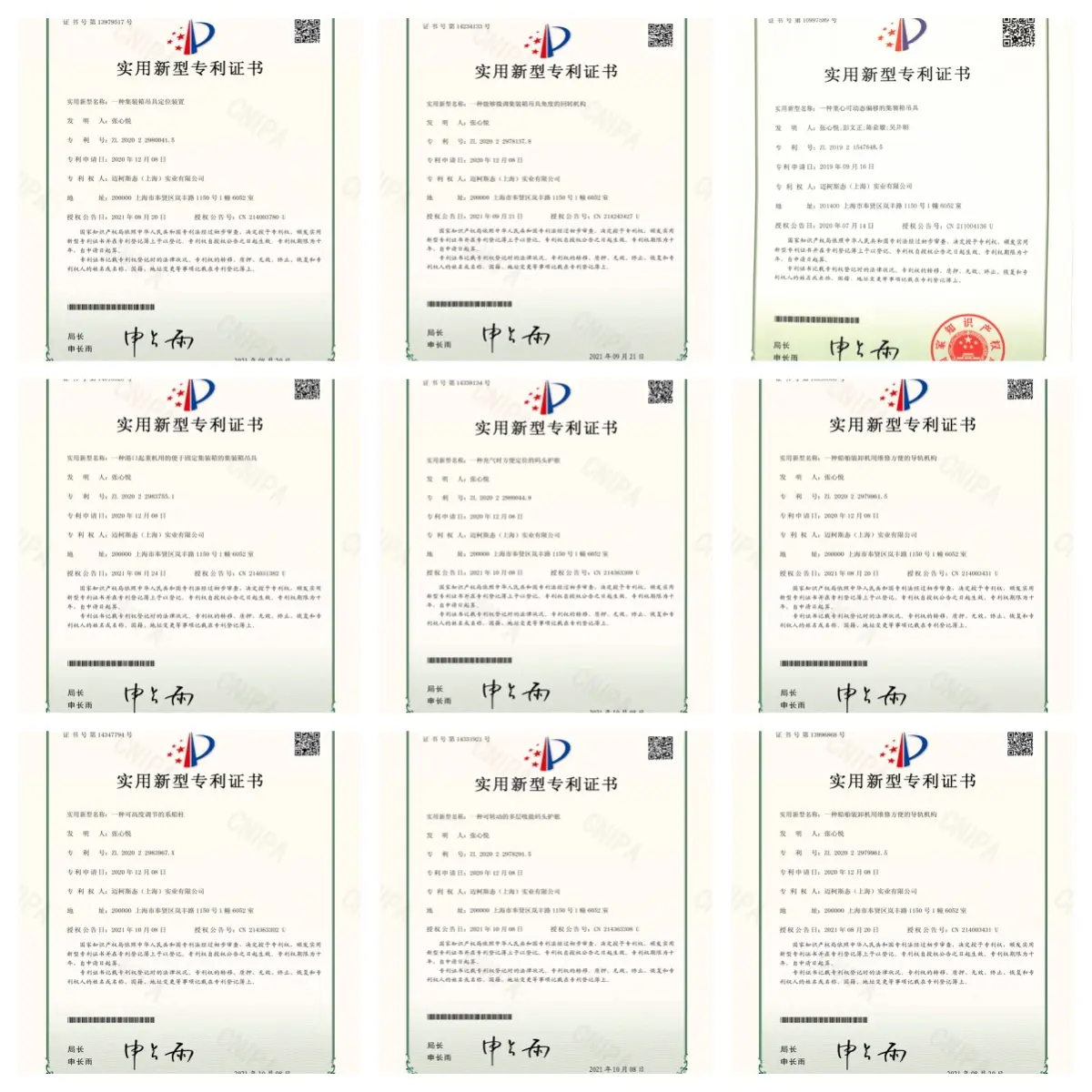

3.Industry Certifications

Quality certificates and factory test reports are provided to provide strong evidence for product quality and allow users to use the product with confidence.Safety Certifications: CE , ISO 9001

We have established cooperative relationships with several renowned enterprises that hold leading positions in their respective fields.

description2