Mobile Harbor Crane With Container Spreader or Grab for Handling Containers or Cargo Bulk

Application

The Maxtech Mobile Harbor Port Crane plays a vital role in the port logistics field.

1.In container handling, equipped with a professional container spreader, it can lift and transport containers quickly and accurately, greatly improving the container turnover efficiency at the dock.

2.For bulk cargo handling, when equipped with a grab, it can easily handle various bulk cargoes such as coal, ore, and grain, realizing efficient bulk cargo loading and unloading operations.

3.In all kinds of ports, whether large comprehensive ports or small specialized terminals, it can ensure the smooth progress of cargo loading and unloading operations with its flexible operation methods and powerful lifting capacity, significantly enhancing the overall operation efficiency of the port.

Model Ranges

Maxtech Mobile Harbor Port Cranes offer a wide variety of models to meet the specific needs of different customers.

1.The lifting capacity spans from 10 tons to 200 tons, allowing users to select the appropriate model according to the actual weight of the goods to be lifted. For scenarios where lighter goods are handled or in limited spaces, models with a lifting capacity of 10 - 30 tons are ideal choices. When it comes to large ports that need to lift heavy equipment and large containers, models with a higher lifting capacity of 100 - 200 tons can handle the task.

Take MAX-280 as an example, the technical parameter is:

| Lifting capacity (max.) | 64 t |

| Max. load bulk | 42 t |

| Radius min. | 9.00 m |

| Jib length | 35 m |

| Total weight | 165 t |

| Container rows max. | 11 |

| Max. ship width bulk | 38 m |

| Max. ship width scrap | 29 m |

| Material handling capacity bulk | 800 t/h |

| Engine power | 400 kW |

| Hoisting/lowering max. | 90 m/min |

| Slewing max. | 1.60 rpm |

| Luffing max. | 83 m/min |

| Travel speed max. | 5.40 km/h |

| Mobility | rubber tyred |

| Fields of application | Bulk handling / Container handling / General cargo operation / Heavy lift / Scrap handling |

| Lifting height max. | 42 m |

2.The working radius can be adjusted between 5 meters and 60 meters. A shorter working radius is suitable for dock areas with limited space, while a longer working radius provides a broader operating range for large open ports.

3.Among them, the 45T@35M multi-functional gantry crane is highly favored in the market due to its excellent comprehensive performance and has been widely used in many Asian ports.

Features

1.Safe and Reliable: Equipped with advanced safety protection systems such as overload protection and anti-collision devices, it comprehensively ensures the safety of operators and equipment. The use of high-quality components and mature design concepts ensures the stability and reliability of the crane under high-intensity operations, providing a solid guarantee for the continuous operation of port operations.

2.Efficient and Compact: The compact body design enables it to move and operate flexibly in limited port spaces. The optimized power system and mechanical structure significantly improve the cargo loading and unloading efficiency, reducing the ship's stay time in the port and bringing higher economic benefits to port operations.

3.Easy to Maintain: It adopts a modular design and easy-to-maintain components, facilitating technicians to conduct daily inspections and maintenance. Clear maintenance markings and operation manuals reduce the difficulty of maintenance. Even during the busy port operation period, the equipment can be quickly maintained to ensure the continuous operation of the crane.

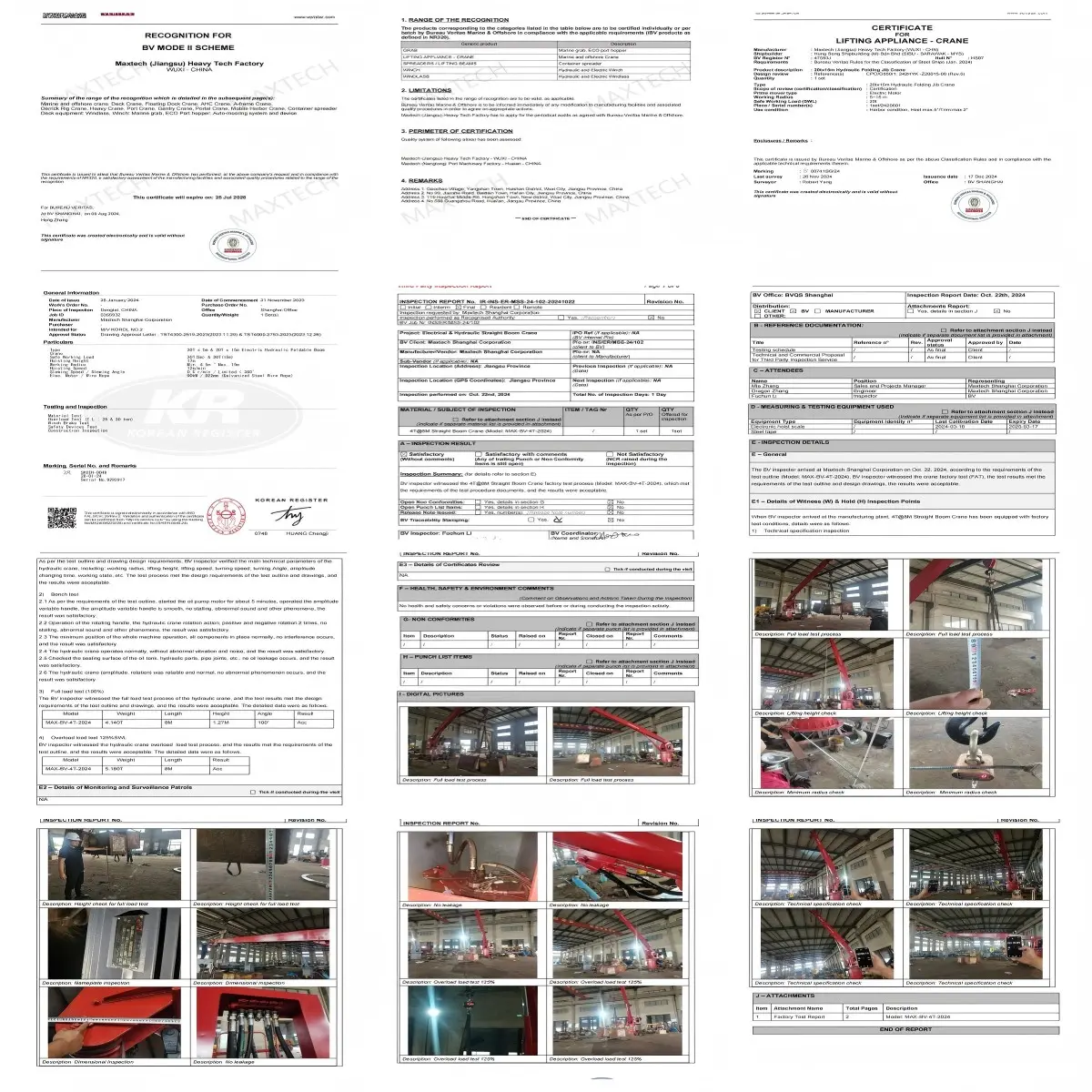

4. Certificates: The product is designed and manufactured in strict accordance with the latest effective specifications of the classification society at the time of contract signing to ensure that the product quality meets industry standards.

5.Customized Service: We understand that the operation requirements of each port are different, so we provide personalized customization services. According to the customer's site conditions, cargo types, and operation requirements, we tailor the crane's parameters and configurations to ensure that the equipment perfectly adapts to the customer's actual needs.

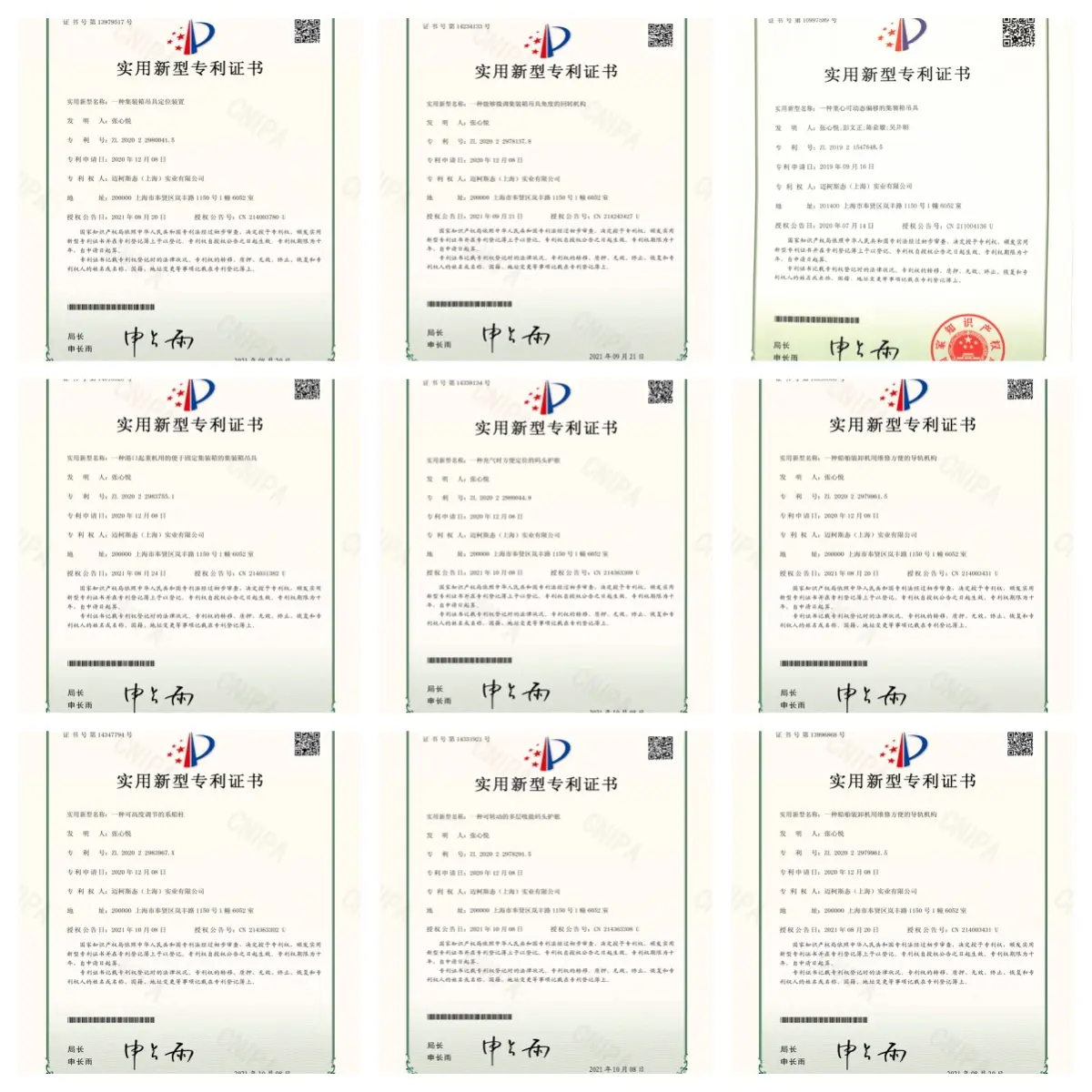

6.Industry Certifications: Quality certificates and factory test reports are provided to provide strong evidence for product quality and allow users to use the product with confidence.Safety Certifications: CE (European Union), ISO 9001(International Organization for Standardization)

7.Cooperation company: We have launched cross-border collaborations with many innovative well-known enterprises, jointly exploring new directions for the future development of the industry.

8.After-sales services: We have a professional after-sales team to provide continuous and timely after-sales support. Whether it is equipment installation and commissioning, operation training, or fault repair, our after-sales team can respond quickly to provide customers with comprehensive technical support, ensuring that customers have no worries during the use process.

description2