Dust Suppression Hopper: A Powerful Assistant in Industrial Material Transportation

In many industrial fields such as grain storage, fertilizer production, quarries, and factories, the transportation of granular or powdered materials is a common operation. However, during this process, dust problems occur frequently, which not only damages the production environment but also leads to material losses. The Dust Suppression Hopper (DSH), that is, the dust - suppressing hopper, has become an ideal solution to these problems.

Reasons Why DSH is Favored

Installation Convenience

The installation process is simple and causes minimal interference with production. There is almost no need to reconfigure existing equipment on a large scale, which greatly saves installation time and costs.

Diverse Sizes

A variety of sizes are available. Whether it is a large - scale enterprise or a small - scale factory, it can find a suitable dust hopper model according to its own production scale, meeting the special needs of different customers.

Economic Benefits Brought by DSH

Reducing Maintenance and Other Costs: After using dust suppression hopper, the costs of maintenance, cleaning, and dust disposal in enterprises have decreased significantly.

Reducing Product Losses: The losses of products caused by dust are reduced, and the shrinkage rate decreases. Enterprises can sell more products, thereby increasing revenue.

Minimizing the Loss of Fine Particles: The loss of fine particles caused by dust dispersion is minimized.

Other Advantages of DSH

Improving the Working Environment

During material loading, the air quality and visibility are significantly improved, which is beneficial to the health of workers and can also improve work efficiency. Some enterprises can even reduce or turn off the original dust extraction equipment, further reducing operating costs.

Speeding up Loading

The loading of trucks, ships, and railway wagons is made faster and cleaner. Each vehicle can be continuously loaded, which greatly shortens the loading time.

Improving Storage Capacity

With a good angle of repose of materials, the materials are stacked more neatly during storage, effectively improving the storage capacity of inventory.

Working Principle of DSH

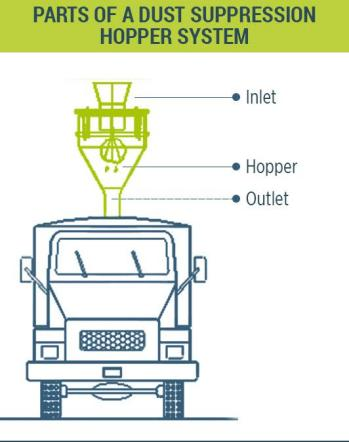

DSH is a patented material discharge device system, mainly used to control the flow rate of flowable materials conveyed through a hopper. Its components are as follows:

Hopper: It serves as the main structure.

Inlet: It is located at the top and is used to receive flowable materials.

Discharge Outlet: It is set at the bottom of the hopper.

Valve: It is configured and installed in the hopper. When materials enter the hopper from the inlet, the valve can accurately control the materials to flow out from the discharge outlet according to the set flow rate, effectively reducing dust generation.

The Position of MAXTECH in the DSH Field

In the field of Dust Suppression Hoppers (DSH), MAXTECH relies on cutting - edge technology and rich industry experience to establish a significant leading edge in R & D and production. Its DSH series products not only ensure excellent dust - suppressing performance but also continuously promote the iterative upgrade of product performance. It customizes highly specialized and reliable solutions for customers, strongly promoting the coordinated development of environmental protection goals and efficient operations in the material transportation process of various industries.