Focusing on Marine Operations: MAXTECH Assists in the Selection of Offshore Cranes, Taking Multiple Factors into Account

OffShore Cranes, essential equipment for operations at sea, are widely utilized across various fields such as marine engineering, offshore oil exploration, sea rescue, and sea cargo transportation. Usually installed on ships, offshore platforms, or other offshore structures, these cranes possess strong lifting capabilities and stability, enabling efficient and safe operations in the harsh marine environment.

During the design and operation of offshore cranes, it is crucial to fully account for the complexity of the marine environment, including factors like wind and waves, sea currents, and seawater corrosion, to ensure the structural strength, stability, and reliability of the cranes. Additionally, to enhance operational efficiency and safety, offshore cranes are also required to have a high level of automation and intelligence.

Diverse Types of Offshore Cranes

Offshore cranes can be classified into various types according to their structure and usage, including Ship Cranes, floating cranes, mast cranes, and more. Each type has its own advantages and disadvantages.

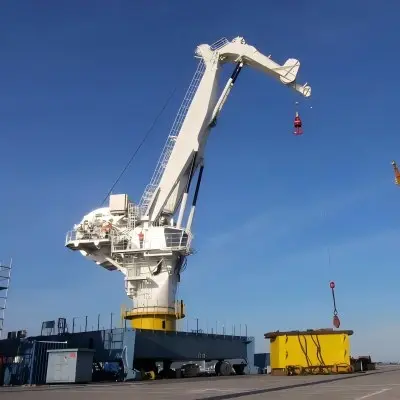

• Ship Cranes: Mainly used for cargo transfer between ships, sea supply, and the placement and recovery of underwater operation equipment. They offer advantages such as high loading and unloading efficiency, easy operation, and small deck area occupation, making them particularly suitable for lifting and loading heavy cargo. However, the large self - weight, large volume, and high center of gravity of ship cranes have a certain impact on the stability of the ship. Moreover, they demand high - level ship power stations and overhaul technologies, and their prices are relatively high.

• Floating Cranes: A commonly used type of offshore crane, consisting of one or more pontoons, can move easily at sea. Their main advantage lies in their mobility, making them suitable for offshore construction, building, demolition, and other tasks. Additionally, floating cranes can be equipped with different types of lifting equipment as needed, such as cradles, bucket cranes, lifting hooks, etc., which greatly enhances their applicability. Nevertheless, their stability may be affected by the offshore environment.

• Mast Cranes: These are lifting equipment based on masts, characterized by a simple structure, ease of use, and suitability for simple lifting operations. They are usually installed on small vessels, with limitations in lifting weight and a relatively narrow scope of application.

Furthermore, offshore cranes can also be divided into electric cranes and hydraulically driven cranes according to the driving method. Electric cranes have advantages such as high efficiency, accurate speed adjustment, easy operation, low maintenance requirements, and easy remote control. Hydraulically driven cranes are characterized by stable operation, light weight, small size, stepless speed regulation, constant power, high speed with empty hooks, and slow speed with light loads.

MAXTECH Shines in the Offshore Crane Field

MAXTECH has been long committed to the research, development, and innovation in the offshore crane field. In product design, it fully considers the complex factors of the marine environment and continuously optimizes the structural strength and stability of cranes to ensure reliable operation under harsh conditions. For example, its newly developed ship crane effectively reduces the impact of its own weight on ship stability through innovative design while improving loading and unloading efficiency. In terms of automation and intelligence, MAXTECH has also invested substantial resources, enabling cranes to achieve more efficient and safer operations. The electric cranes produced by MAXTECH perform outstandingly in terms of operation accuracy and efficiency with their advanced control systems, winning wide recognition in the market.

Multiple Factors to be Considered in Selecting Offshore Cranes

When choosing the type of offshore crane, multiple factors need to be comprehensively considered:

• Lifting Requirements: Clearly define the specific needs of offshore lifting operations, including the weight, size, and shape of the cargo to be lifted. This will determine the required lifting capacity and working range of the crane.

• Working Environment: The offshore working environment is complex and changeable. The stability and adaptability of the crane need to be considered. For instance, floating cranes are suitable for operational scenarios that require frequent movement, while ship cranes are suitable for cargo transfer between ships.

• Equipment Characteristics: Different types of offshore cranes have distinct characteristics. Electric cranes are highly efficient, accurate in speed adjustment, and easy to operate, making them suitable for scenarios with high requirements for operational efficiency. Hydraulically driven cranes feature stable operation and stepless speed regulation, making them suitable for operations with high - precision requirements.

• Safety Requirements: Offshore lifting operations have extremely high safety requirements. When choosing an offshore crane, its safety performance and reliability need to be considered. For example, the structural strength, stability, braking system, and safety guards of the crane must meet relevant standards and requirements.

• Economic Factors: This includes the acquisition cost, maintenance cost, operating cost, and service life of the crane. A comprehensive consideration based on actual needs and budgets is necessary to select the most cost - effective offshore crane.

Choosing the type of offshore crane requires a comprehensive consideration of lifting requirements, working environment, equipment characteristics, safety requirements, and economic factors. Through comprehensive evaluation and analysis, the most suitable type of offshore crane for actual needs can be selected to improve operational efficiency and safety. MAXTECH, with its advantages in technology research and development and product innovation, is injecting strong impetus into the development of the industry.