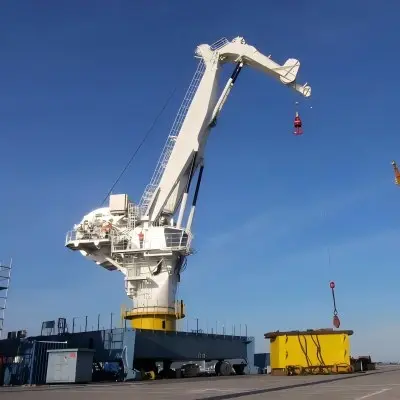

Foreign Customers Visit MAXTECH to Inspect 3t39m Telescopic Boom Crane Production

May 26th, MAXTECH welcomed important foreign customers who made a special trip to inspect the production of 3t39m telescopic boom cranes. These Cranes are highly versatile and suitable for a wide range of applications, includingmarine crane operations, ship crane tasks, and port crane duties. Previously, the customer had placed an order for three such cranes with MAXTECH, acknowledging their potential in various maritime and port-related projects.

One of them was successfully dispatched to Egypt on May 23rd, and currently, MAXTECH's professional engineering team is intensively carrying out on-site installation work in Egypt. This crane is expected to play a crucial role in Port Crane operations at the local busy ports, handling tasks such as container handling and ship replenishment. As for the remaining two cranes, the MAXTECH factory is fully engaged in production to ensure timely delivery, with a focus on meeting the high standards required for offshore crane applications as well.

During this visit, the customers delved deep into the production workshop and paid close attention to every aspect of crane production. In particular, they meticulously inquired about the process details and quality control measures in the manufacturing and assembly of key components. For example, in the telescopic boom manufacturing area of the crane, the customers thoroughly understood the selection criteria for steel materials, welding processes, and the control of boom processing precision. Technicians from MAXTECH introduced to the customers that, to ensure the reliability of the telescopic boom during high-intensity operations, the company selects high-quality high-strength steel and employs advanced automated welding equipment to ensure that the weld quality reaches international leading standards. These manufacturing standards are essential for the cranes to function optimally in demanding environments, whether it's as a marine crane assisting in oceanic operations or an offshore crane working in harsh offshore conditions. Moreover, after each production process is completed, a strict quality inspection process is in place, and only components that pass the inspection can proceed to the next process, ensuring that every crane leaving the factory meets the stringent requirements for ship crane and other maritime applications.

The customers also showed a keen interest in the crane's hydraulic system. MAXTECH's hydraulic system was developed in collaboration with renowned hydraulic experts in the industry. It is equipped with advanced pump and brake safety monitors, which can continuously monitor the system's operation status to ensure the safety and stability of the crane during operation. This feature is of utmost importance for marine cranes and offshore cranes, where reliability can significantly impact the success of maritime projects. After listening to the introduction, the customers watched the on-site debugging demonstration of the hydraulic system and highly commended MAXTECH's innovation and reliability in hydraulic technology, recognizing its value for various crane applications in the marine and port sectors.

Relevant responsible persons from MAXTECH stated that the customers' personal visit to the factory for inspection reflects their high regard and trust in the company's products. Taking this visit as an opportunity, the company will further optimize the production process and enhance product quality to ensure that the remaining two cranes can be delivered to the customers on time and with high quality. Given the diverse applications of these cranes, from port crane operations to offshore crane tasks, MAXTECH is committed to delivering equipment that excels in all scenarios. Meanwhile, the company also looks forward to establishing a more long-term and stable cooperative relationship with the customer to jointly explore the international market, aiming to expand the presence of their high-quality cranes, including marine cranes, ship cranes, port cranes, and offshore cranes, in global maritime and port industries.

It is reported that MAXTECH's 3t39m telescopic boom cranes are highly favored in the international market due to their excellent performance and reliable quality, and are widely used in various fields such as luxury yachts, marine scientific research, engineering vessels, oil field operations, and coast guard. The crane dispatched to Egypt this time will be mainly used for important tasks such as container handling and ship replenishment at the local busy ports, injecting new vitality into Egypt's maritime trade and shipping industry. With their adaptability and high performance, these cranes are set to become an integral part of the region's marine crane and port crane infrastructure, facilitating smooth and efficient maritime operations.