0102030405

Marine Deck Crane: Innovating Hydraulic Technology for Efficient Maritime Lifting

2025-07-21

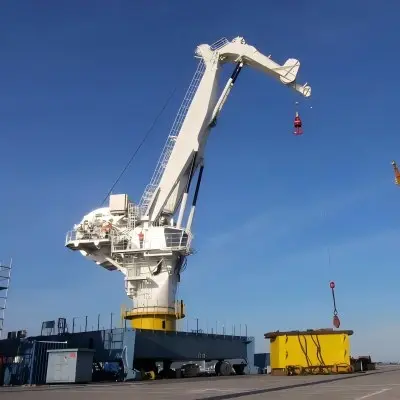

Marine deck cranesare the backbone of cargo handling on transport ships, ensuring safe and efficient loading and unloading across general cargo ships, container vessels, bulk carriers, and engineering ships—whether navigating international oceans or domestic waterways. A leading innovation in lifting equipment has redefined performance in this field with advanced marine Deck Cranes, highlighted by a groundbreaking hydraulic system and a suite of intelligent features. These cranes not only meet the rigorous demands of maritime operations but also set new standards for energy efficiency and safety.

A Revolutionary Hydraulic Breakthrough: Closed System Takes Center Stage

At the core of these marine deck cranes lies a pivotal innovation: the adoption of a closed hydraulic system—a departure from the traditional open systems commonly used in deck cranes. This shift addresses long-standing challenges in lifting brake control, a critical pain point in maritime lifting where precision and reliability are non-negotiable.

The advantages of this closed system are transformative:

- Dramatic Energy Savings: Hydraulic oil consumption is reduced by over 50% compared to open-system cranes, minimizing fluid waste and lowering operational costs. Concurrently, power consumption is significantly cut, aligning with global trends toward greener maritime practices.

- Enhanced Control Precision: The closed-loop design enables finer regulation of lifting speed and brake response, even under dynamic conditions like ship sway or varying cargo weights. This stability is especially valuable for container handling and bulk cargo operations, where sudden load shifts can risk safety.

This innovation alone has earned the deck cranes recognition, contributing to a portfolio of 6 national patents that underscore the technology’s uniqueness and effectiveness.

Integrated Features: Safety, Intelligence, and Adaptability

These marine deck cranes are engineered as holistic solutions, combining mechanical, electrical, and hydraulic systems into a seamless operation. Key features include:

- Machine-Electric-Hydraulic Integration: The crane’s systems work in unison, with real-time data sharing between components. This integration ensures smooth transitions between lifting, luffing, and slewing motions, reducing downtime and enhancing operational flow.

- Full Hydraulic Drive: Driven entirely by hydraulic power, the crane delivers consistent performance across all functions—from heavy lifts to delicate positioning. This design eliminates the complexity of mixed power sources, simplifying maintenance and improving reliability in harsh marine environments.

- Self-Diagnosing Heave Compensation: Marine operations are plagued by ship motion, but the system automatically detects wave-induced heave and adjusts the crane’s movements to stabilize loads. This feature is critical for safe cargo transfer in rough seas, reducing the risk of sway-related accidents.

- Luffing Load Horizontal Movement: When adjusting the crane’s boom angle (luffing), the system maintains the load’s horizontal position, preventing unnecessary swinging or shifting. This precision is invaluable for loading delicate cargo or positioning items in tight spaces, such as a ship’s hold.

- Eight-Tier Safety Protection: Safety is paramount, and these cranes are equipped with a comprehensive suite of safeguards, including a torque limiter (prevents overload), emergency stop functions, anti-collision sensors, and pressure relief valves. Together, they create a multi-layered defense against operational risks.

- Visible Safety Monitoring System: Operators and supervisors gain real-time insights through a digital monitoring interface, displaying critical data such as load weight, boom angle, hydraulic pressure, and system health. This transparency allows for proactive decision-making and rapid response to anomalies.

Designed for the Maritime World

These marine deck cranes are purpose-built for the diverse challenges of international and domestic shipping. Whether deployed on bulk carriers hauling ore, container ships managing stacked cargo, or engineering vessels supporting offshore projects, they excel in:

- Corrosion Resistance: Materials and coatings are tested to withstand salt spray, humidity, and extreme temperature fluctuations, ensuring longevity in harsh marine climates.

- Space Efficiency: Compact designs adapt to limited deck space, with foldable components where needed to avoid interference with other ship systems.

- Operational Versatility: From heavy lifts (supporting tons of cargo) to precise maneuvers (positioning containers), the cranes adapt to varying loads and mission requirements.

In an industry where efficiency, safety, and sustainability are increasingly critical, these marine deck cranes stand out as a testament to innovative engineering. By reimagining hydraulic systems and integrating intelligent features, they not only streamline cargo handling but also pave the way for greener, more reliable maritime operations—proving that even in the toughest environments, technology can lift performance to new heights.