MAXTECH Bulk Cargo Grab: The Premier Solution for Bulk Material Handling-1

1. Overview and Design Philosophy

The MAXTECH Bulk Cargo Grab stands as a testament to innovation and engineering excellence in the realm of bulk material handling. As a general - purpose tool, it is meticulously designed to handle an extensive range of bulk materials, such as coal, ore, grains, and construction aggregates. Its primary function is to efficiently scoop up and transport large volumes of these materials, facilitating seamless operations from a ship’s hold to storage facilities or directly onto conveyor belts for further processing.

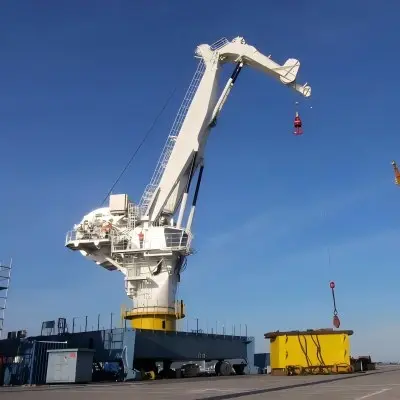

Mounted on Cranes, excavators, or other heavy - lifting equipment, the MAXTECHBulk Cargo Grab features a robust and durable design. Constructed from high - strength alloy steel, it can withstand the harshest industrial environments and the rigors of continuous use. The grab’s structure is engineered to distribute stress evenly, minimizing the risk of structural failure and ensuring long - term reliability.

2. Diverse Sizes and Configurations

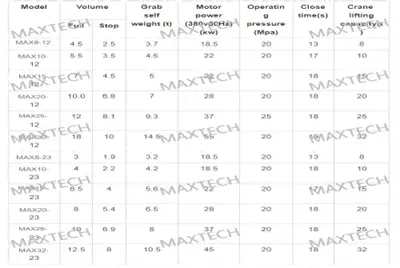

MAXTECH offers a wide array of Bulk Material Grab sizes and configurations to meet the specific needs of different industries and material handling requirements:

Size Range: Available in sizes with a capacity ranging from 1 cubic meter to 30 cubic meters. For example, the smaller 1 - 2 cubic meter models are ideal for handling light - density materials like grains in agricultural settings, while the larger 20 - 30 cubic meter Grabs are well - suited for heavy - duty applications in mining and port operations, such as loading and unloading iron ore.

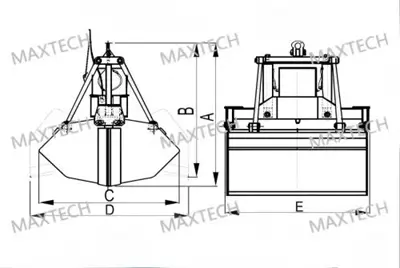

Below are the size range and reference drawing of Maxtech’s bulk cargo grabs:

Specialized Configurations:

Teeth - Equipped Models: Some grabs are fitted with high - hardness alloy teeth. These teeth have a hardness of up to HRC60, enabling them to easily break up compacted materials like coal or tightly packed construction aggregates. The tooth design also ensures a firm grip on the material, preventing slippage during transportation.

Smooth - Interior Models: In contrast, other models feature a smooth interior surface with a surface roughness of Ra 0.8. This design significantly reduces friction and spillage, making it perfect for handling fine - grained materials such as cement or fertilizers.

3. Core Technical Parameters

The MAXTECH Bulk Handling Grab comes with a set of impressive technical parameters that contribute to its superior performance:

Opening and Closing Speed: The grab can achieve an opening and closing speed of 0.8 - 1.2 m/s, depending on the model. This fast cycle time significantly improves the overall handling efficiency, increasing the throughput of materials in a given time frame.

Lifting Capacity: With a maximum lifting capacity of up to 50 tons (varies by model), it can handle heavy loads with ease. The load - bearing structure is designed to meet or exceed international safety standards, ensuring the safe operation of the grab under heavy loads.

Power Consumption: The power consumption of the grab is optimized, with an average power draw of 15 - 50 kW (depending on size and configuration). This energy - efficient design not only reduces operating costs but also makes it more environmentally friendly.

4.Operational Applications

The MAXTECH Mass Cargo Grab finds extensive applications across multiple industries:

Mining Industry: In open - pit mines, it is used to load extracted ore onto trucks or conveyor belts for transportation to processing plants. Its ability to handle large volumes of heavy materials in a short time helps increase the productivity of mining operations.

Shipping Industry: At ports, the grab is employed to unload bulk cargo from ships’ holds. Its versatility allows it to handle different types of materials, reducing the need for multiple specialized handling equipment. This streamlines the port operations and cuts down on handling time and costs.

Construction Industry: For construction projects, the grab is used to transport construction aggregates such as sand, gravel, and crushed stone. It can directly load these materials onto construction sites, facilitating the building process and ensuring a continuous supply of essential materials.

5.Technical Advantages of MAXTECH

MAXTECH's Bulk Cargo Grab offers several unique technical advantages:

Advanced Control System: It is equipped with an intelligent control system that allows for precise adjustment of the grab’s opening and closing force. This ensures that the grab can handle different materials without causing damage, whether it's the gentle handling of grains or the firm grip on heavy ores.

Wear - Resistant Components: Key components of the grab, such as the hinge pins and bucket edges, are made from wear - resistant materials. These components have a service life of up to 5,000 working hours under normal operating conditions, reducing maintenance costs and downtime.

Easy Installation and Maintenance: The grab is designed for quick and easy installation on various types of heavy - lifting equipment. Its modular structure also makes it convenient for component replacement during maintenance, minimizing the time required for servicing and keeping the equipment up and running with minimal disruption.