MAXTECH Unveils Comprehensive Guide to Marine Cranes: Types, Functions, and Considerations

Gantry Crane

1. Function: Gantry Cranes are the workhorses of port operations, primarily used for loading and unloading containers from ships. Their towering structure and rail - traversing ability enable high - volume cargo movement.

2. Key Considerations: Shipowners must ensure port infrastructure compatibility, as these Marine Cranes require a robust rail system and reliable power supply. Investing in automated operations and weather - resistant customization can enhance long - term efficiency and durability. For high - throughput ports, a twin - lift capable gantry crane can double cargo - handling speed.

Jib Crane

1. Function: Versatile and compact, jib cranes are ideal for general cargo handling on ships. Their 360 - degree rotation feature allows for flexible operations, making them suitable for various cargo types, especially on smaller vessels.

2. Key Considerations: Strategic placement on the ship's deck is crucial to maximize coverage. Precise rotation and regular maintenance, especially greasing of pivot points in salty environments, are essential. Customizing the boom length according to cargo needs also optimizes performance.

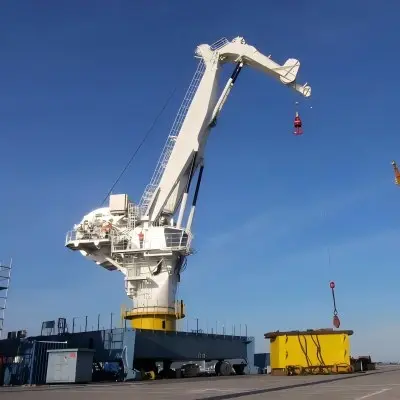

Knuckle Boom Crane

1. Function: Renowned for their compact design and versatility, knuckle boom cranes are perfect for operations in confined spaces, such as on offshore support vessels. Their folding boom allows for space - saving when not in use.

2. Key Considerations: Training the crew to operate the folding mechanism efficiently is important to avoid hydraulic wear. For offshore use, cranes with advanced stabilization and hydraulic dampening systems are recommended. Self - lubricating bearings can significantly reduce maintenance requirements.

Telescopic Boom Crane

1. Function: With an extendable boom, telescopic boom cranes offer variable reach, making them adaptable to different cargo operations. They can handle a wide range of cargo sizes, from small packages to large, bulky items.

2. Key Considerations: Crew training on effectively using the adjustable boom is vital. Investing in cranes with enhanced stability features is necessary to prevent tipping when the boom is fully extended. Regular inspection and lubrication of telescopic mechanisms, along with integration with digital controls for precision handling, are also important.

Luffing Crane

1. Function: Luffing cranes are designed for high - precision lifting, with the ability to raise and lower the jib. They are ideal for ships handling heavy, awkwardly shaped loads, especially in space - limited scenarios.

2. Key Considerations: Operators need specialized training to control the boom angle efficiently. Paying close attention to weight distribution on the ship when using these ship cranes is crucial to avoid tilting. Regular maintenance of the hydraulic systems that control the boom's movement is essential to prevent malfunctions.

Pedestal Crane

1. Function: Mounted on a fixed pedestal base, pedestal cranes are versatile and stable, commonly used on various ships for general cargo handling. Their fixed position provides a reliable lifting platform in different sea conditions.

2. Key Considerations: Strategic deck positioning is essential to maximize coverage without obstructing other operations. Enhancing stability through structural reinforcements, especially on smaller vessels or in rough seas, is important. Ensuring easy access for maintenance and being aware of the load capacity are also key factors.

Sheerlegs (Floating Crane)

1. Function: Specialized for heavy - lifting operations like salvage, offshore construction, and port activities, sheerlegs are mounted on a barge or pontoon, offering mobility to reach different locations.

2. Key Considerations: Mobility requires careful navigation planning, especially in rough seas. Investing in advanced stabilization systems is crucial to maintain balance during heavy lifts. Crew training in both crane operation and barge handling, along with regular structural inspections of the barge, is essential.

Grab Crane

1. Function: Equipped with a clamshell bucket, grab cranes are designed for handling bulk materials such as coal, ore, and grain. They are commonly used in ports and on bulk carriers.

2. Key Considerations: Optimizing the bucket size for typical cargo, choosing wear - resistant materials to combat abrasion, investing in dust control systems, and considering automation upgrades for repetitive tasks can all enhance efficiency.

Subsea Crane

1. Function: Engineered for underwater operations, subsea cranes are crucial for the offshore oil and gas industries. They perform precise lifting and placement of heavy equipment on the seabed.

2. Key Considerations: Investing in cranes with advanced dynamic positioning systems for precise underwater lifts, ensuring pressure - resistant design, having reliable remote operation capabilities, and scheduling regular deep - sea maintenance are all necessary.

Platform Crane

1. Function: Essential on offshore platforms, platform cranes handle materials and equipment for drilling, production, and maintenance operations. Their robust design withstands harsh offshore environments.

2. Key Considerations: Using corrosion - resistant materials, equipping with weather - adapted features like wind speed monitoring and automatic shutdown systems, planning regular maintenance, and integrating load monitoring systems are important for long - term performance.

Lattice Boom Crane

1. Function: Known for their stability and high lifting capacity, lattice boom cranes are ideal for heavy - lifting tasks in shipbuilding, construction, and salvage operations. Their lattice structure reduces weight while maintaining strength.

2. Key Considerations: Customizing the boom length according to specific lifting requirements, ensuring proper alignment of the base and boom for enhanced stability, conducting detailed assembly and regular inspections of connections, and incorporating load swing control systems are key.

Portal Crane

1. Function: Also known as goliath cranes, portal cranes are used in shipyards and ports for heavy - lifting tasks such as shipbuilding, repair, and cargo handling. They move on rails and can lift and move massive loads across large areas.

2. Key Considerations: Infrastructure investment, including precise rail laying and a strong foundation, is significant. Considering their versatile applications for long - term needs, regular rail maintenance, and integrating advanced safety systems are essential for smooth operations.