Transshipment Crane MAX 500 E: A Superior All-electric Solution

Application

The MAX 500 E transshipment crane excels in multiple applications. It can be widely used in ports and harbors for the rapid and efficient loading and unloading of containers and bulk cargo. In sheltered water areas, it can handle a maximum load of 90 tons in grab operation, while in open water, it can manage up to 65 tons. This makes it suitable for both calm and more challenging marine environments, supporting diverse maritime logistics and cargo handling needs.

Model Ranges

|

Operation |

Safe Working Load (SWL) |

Speed Range |

| Hoisting/Lowering | Up to 32 t SWL | 0 m/min – 140 m/min |

| Hoisting/Lowering | 50 t SWL | 0 m/min – 110 m/min |

| Hoisting/Lowering | 65 t SWL | 0 m/min – 85 m/min |

| Hoisting/Lowering | 75 t SWL | 0 m/min – 74 m/min |

| Hoisting/Lowering | 90 t SWL | 0 m/min – 61 m/min |

| Hoisting/Lowering | 105 t SWL | 0 m/min – 53 m/min |

| Slewing | - | Speed: 0 rpm – 1.6 rpm Range: 360° unlimited |

| Luffing | - | Maximum luffing: 0 – 85 m/min (Design conditions) |

| Design Conditions - Heel/Trim | - | Maximum admissible: 5°/2° or 2°/5° |

| Design Conditions - Temperature | - | Ambient working temperature: -20°C to +45°C |

| Design Conditions - Wind Speed | Working condition | 20 m/sec (0.245 kN/m²) |

| Design Conditions - Wind Speed | Parking condition | 63 m/sec |

Features

1.All-electric Driven: The all-electric drive system not only ensures efficient operation but also reduces environmental impact, making it a sustainable choice for modern transshipment operations.

2.Precise and Reliable Control: Equipped with MAXTECH crane control system, it offers precise and reliable operation, ensuring accurate handling of cargo and enhanced safety.

3.Simplified Maintenance: The use of electrical components simplifies the maintenance process, reducing downtime and maintenance costs, and improving overall operational efficiency.

4.Energy-efficient: the crane can effectively recycle and reuse energy, significantly reducing energy consumption and operating costs.

5.Closed Water Cooling System: The closed water cooling system for power electronics ensures stable performance even under high-intensity operation and harsh environmental conditions.

6.Customization: It can fulfill customer-specific requirements through a wide variety of crane configurations and options, adapting to different application scenarios and needs.

7.High Turnover Performance: In dry bulk handling, it can achieve a remarkable turnover performance of up to 2,000 tons per hour, greatly enhancing the efficiency of cargo handling operations.

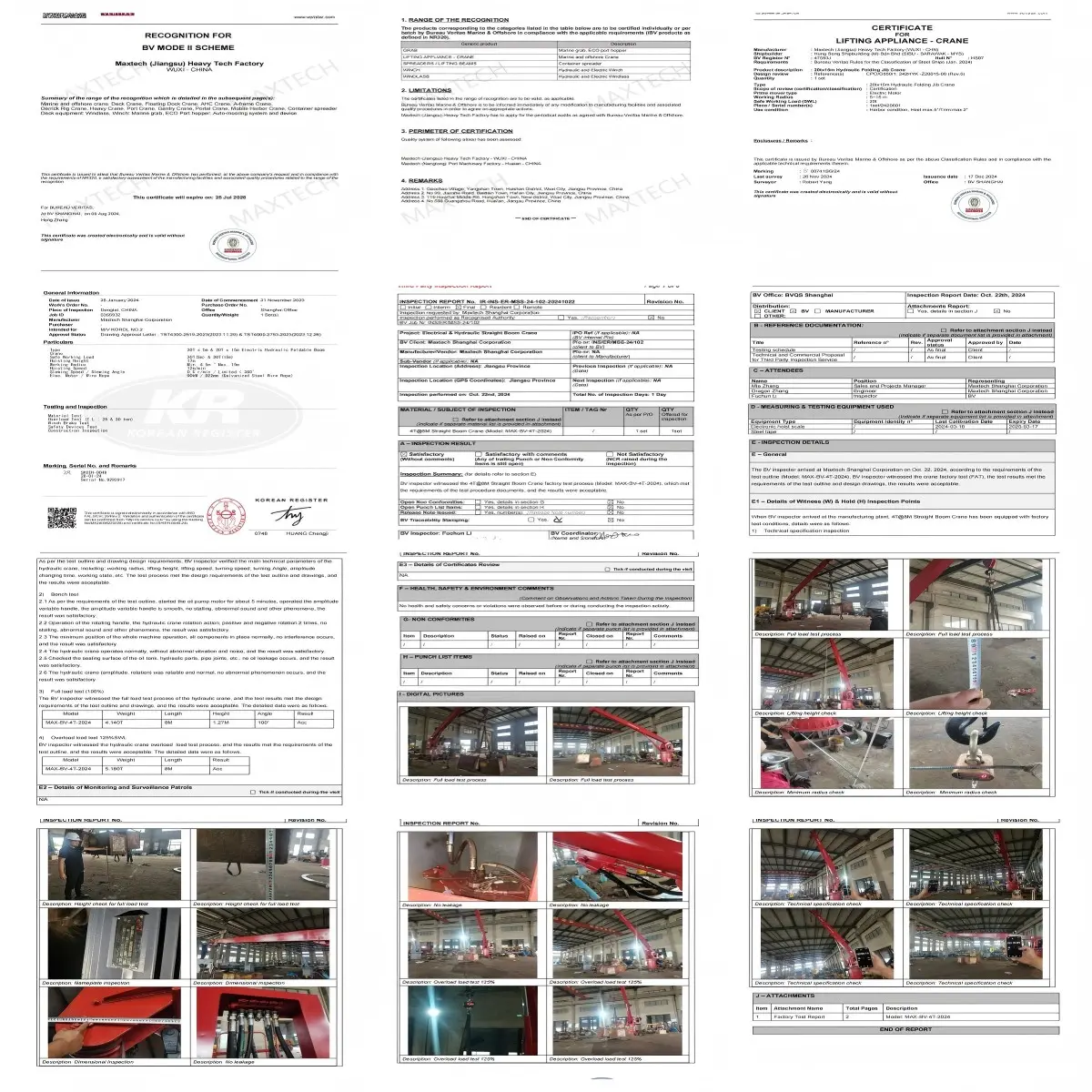

Certificates and Qualifications:

2.Testing and Certification

Before leaving the factory, the equipment needs to undergo strict tests, including performance tests (lifting, luffing, and slewing movements with rated and overload loads), emergency stop confirmation, manual brake release tests, limit switch confirmation (under no - load conditions), and insulation resistance measurement. The test records of each item will be submitted to users to ensure reliable product performance.

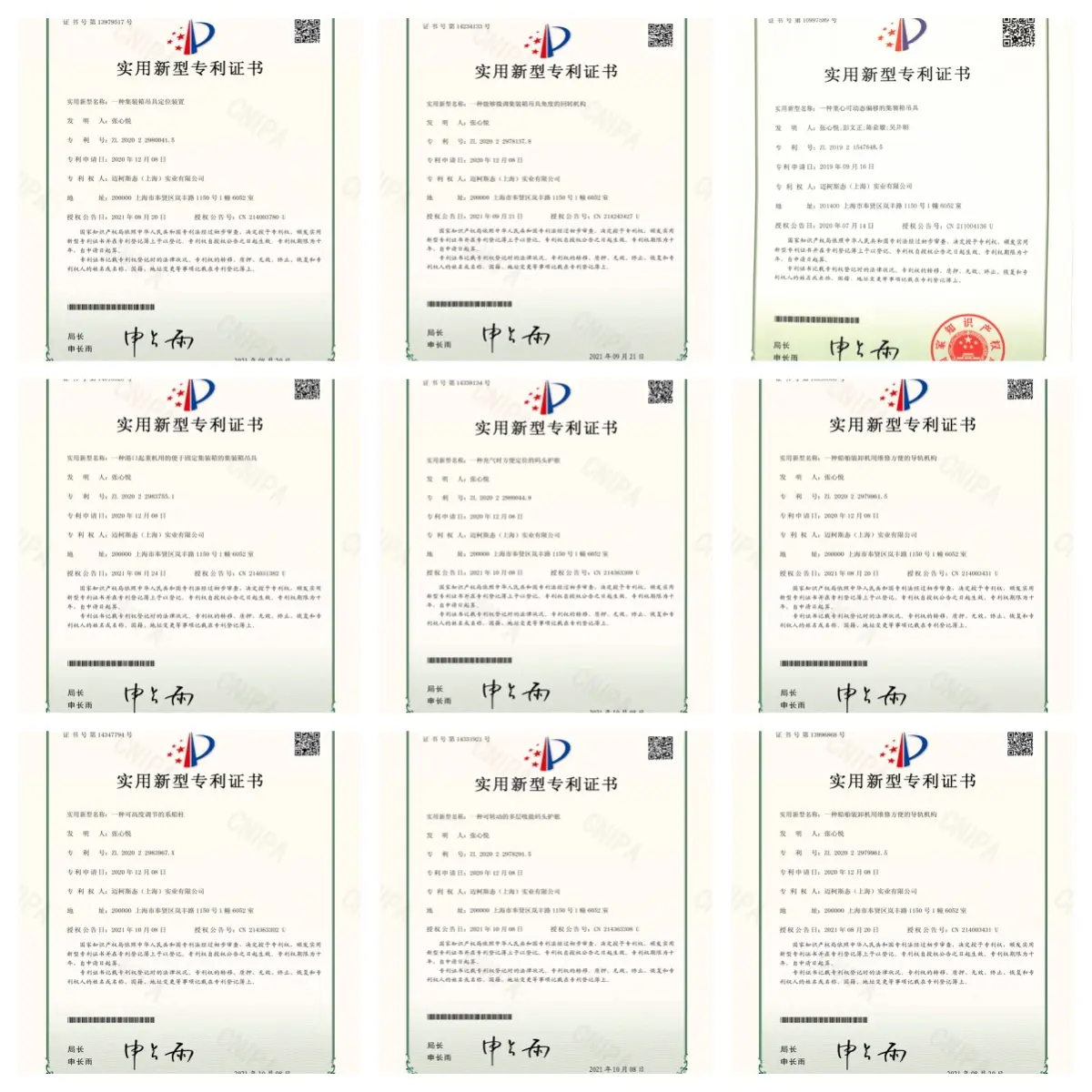

3.Industry Certifications

Quality certificates and factory test reports are provided to provide strong evidence for product quality and allow users to use the product with confidence.Safety Certifications: CE , ISO 9001

We have established cooperative relationships with several renowned enterprises that hold leading positions in their respective fields.

description2